Process optimisation for pilot-scale production of maple bark extracts, natural sources of antioxidants, phenolics, and carbohydratesThibaud R. Geoffroy, Yves Fortin, and Tatjana Stevanovic Université Laval, Quebec, Canada

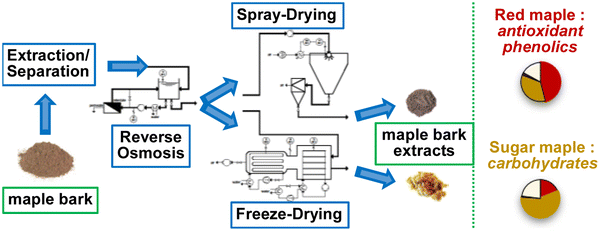

E-mail: tatjana.stevanovic@sbf.ulaval.ca Abstract: The growing customer demand in safer food additives leads the food industry to investigate new sources of bioactive compounds. In addition, the need for “greener” production processes makes aqueous extractions of by-products from plant or wood processing increasingly attractive. Based on recent studies demonstrating the biological properties of the constituents from maple bark, this paper investigates sustainable ways of efficiently producing red and sugar maple bark extracts (RMBE and SMBE) as antioxidant food additives. Several ways to obtain dried extracts were investigated considering the final quality of the extracts (antioxidant capacity, total phenolic, sugar, and protein contents), the extract recovery, and energy consumption of the process. Optimising the concentration and drying steps using principal component analysis provided two optimal variants of the process. Reverse osmosis/freeze-drying appeared to maximise extract quality, while reverse osmosis/spray-drying allowed the lowest power consumption for a sufficient quality. Optimal extracts from both species provided moderate-to-high ORAC and EC50 DPPH· values compared to recognised natural food additives confirming their interest for antioxidant enrichment. Considering the favourable repeatability between pilot-scale production processes for RMBE and SMBE despite their distinct chemical profiles, this study could provide a decent basis to investigate the optimal processing of other water-extractable materials. Keywords: Maple bark extract ; Antioxidant ; Food additive ; Process optimisation ; Principal component analysis Full paper is available at www.springerlink.com. DOI: 10.1007/s11696-017-0355-9

Chemical Papers 72 (5) 1125–1137 (2018) |

Friday, April 04, 2025 |

|||

© 2025 Chemical Papers |

||||