The influence of NOx presence on the catalytic N2O decomposition over the supported double-promoted cobalt spinel catalystMarek Inger, Jakub Rajewski, Monika Ruszak, and Marcin Wilk New Chemical Syntheses Institute, Puławy, Poland

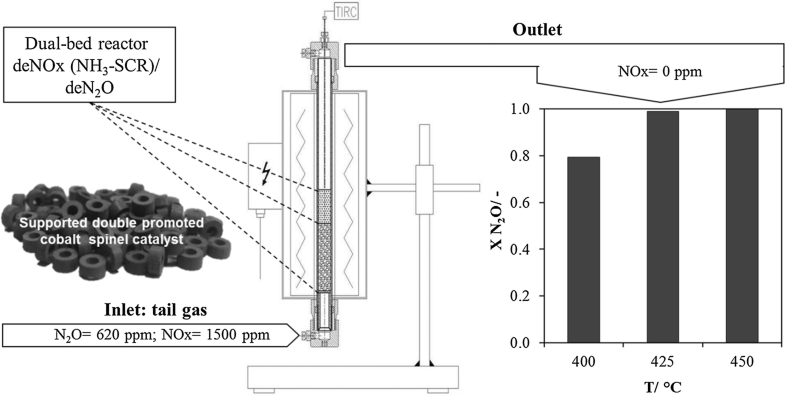

E-mail: jakub.rajewski@ins.pulawy.pl Abstract: The supported double-promoted cobalt spinel catalyst has been tested for N2O decomposition in the model and real gas streams (tail gas) from nitric acid plant. Activity tests carried out in the model gas stream showed a high activity of the developed supported catalyst. However, during catalytic investigations performed under real industrial conditions it was found that this catalyst is very sensitive to NOx poisoning. The negative influence of these oxides is visible even at their low concentration. However, the stability tests performed in real nitric acid plant gas streams showed that the developed catalyst preserves its initial activity for at least 40 days. Therefore, the authors propose to apply it in a dual-bed catalytic system consisting of deNOx and deN2O catalyst beds. At the first stage, tail gas is purified from NOx in the NH3-SCR process in the presence of commercial catalyst and at the second stage, catalytic decomposition of N2O into N2 and O2 takes place over the developed supported cobalt spinel catalyst. The deNOx catalyst bed applied in the proposed dual-bed catalytic system allowed for the complete conversion of NOx from the tail gases. After installation of the supported cobalt spinel catalyst downstream of the deNOx catalyst bed, a significant increase in deN2O catalyst activity in the real tail gas stream was observed. Under optimal conditions, this system (F = 150 L/h; T = 425–450 °C) allowed for the complete reduction of N2O emission. It is shown that the proposed catalytic system is robust and allows to obtain high conversions of both NOx and N2O. Keywords: Low-temperature N2O decomposition ; Supported cobalt spinel catalyst ; Dual-bed catalytic reactor Full paper is available at www.springerlink.com. DOI: 10.1007/s11696-019-00750-9

Chemical Papers 73 (8) 1979–1986 (2019) |

Tuesday, November 26, 2024 |

|||

© 2024 Chemical Papers |

||||